Long Island's masonry landscape is evolving fast. Smart materials, sustainable solutions, and game-changing installation methods are reshaping how contractors approach projects.

Share:

Summary:

The days of guessing about structural integrity are ending. Smart masonry materials now integrate sensors and IoT connectivity directly into building components, giving you real-time data about stress, temperature, and even seismic activity.

These aren’t science fiction concepts—they’re available today. Smart bricks can detect structural issues before they become visible problems, potentially saving thousands in repair costs and liability concerns. For Long Island contractors dealing with coastal weather patterns and ground movement, this technology offers unprecedented project monitoring capabilities.

The practical applications extend beyond monitoring. Some systems can automatically alert property managers when maintenance is needed, creating new service opportunities for contractors who understand the technology.

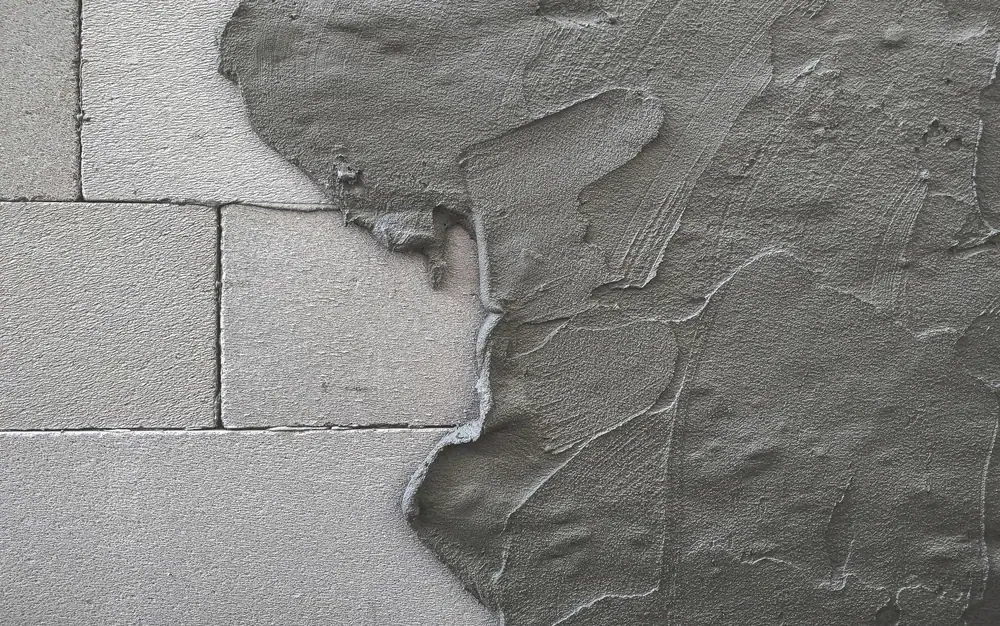

Here’s something that sounds impossible but works: mortar that repairs its own cracks. Advanced formulations now include embedded bacteria or chemical agents that activate when moisture enters a crack, essentially healing the damage automatically.

For Long Island’s challenging climate—with freeze-thaw cycles that traditionally wreak havoc on masonry joints—self-healing mortars represent a significant breakthrough. Instead of scheduling regular repointing work, these materials maintain their integrity for decades with minimal intervention.

The technology works through dormant bacteria that become active when exposed to water and air through cracks. These bacteria produce limestone, effectively sealing the crack from the inside out. While the initial material cost runs higher than traditional mortar, the long-term maintenance savings often justify the investment within the first few years.

Early adopters are seeing remarkable results in harsh environments. One Long Island commercial project using self-healing mortar showed zero maintenance requirements after three years in a high-exposure coastal location where traditional mortar typically needs attention within 18 months.

The installation process remains familiar to experienced masons, but mixing procedures require more precision. Training your crew on proper handling ensures you get the full benefit of this technology while maintaining the quality standards your clients expect.

Here’s something that sounds impossible but works: mortar that repairs its own cracks. Advanced formulations now include embedded bacteria or chemical agents that activate when moisture enters a crack, essentially healing the damage automatically.

For Long Island’s challenging climate—with freeze-thaw cycles that traditionally wreak havoc on masonry joints—self-healing mortars represent a significant breakthrough. Instead of scheduling regular repointing work, these materials maintain their integrity for decades with minimal intervention.

The technology works through dormant bacteria that become active when exposed to water and air through cracks. These bacteria produce limestone, effectively sealing the crack from the inside out. While the initial material cost runs higher than traditional mortar, the long-term maintenance savings often justify the investment within the first few years.

Early adopters are seeing remarkable results in harsh environments. One Long Island commercial project using self-healing mortar showed zero maintenance requirements after three years in a high-exposure coastal location where traditional mortar typically needs attention within 18 months.

The installation process remains familiar to experienced masons, but mixing procedures require more precision. Training your crew on proper handling ensures you get the full benefit of this technology while maintaining the quality standards your clients expect.

Want live answers?

Connect with a Powerhouse Mason Supply expert for fast, friendly support.

Installation efficiency directly impacts your profitability, and new paver systems are cutting installation time dramatically. Lightweight alternatives now weigh one-third as much as traditional concrete pavers while maintaining equivalent strength and durability.

Large format pavers—some reaching 32″ x 48″—reduce the number of individual pieces needed for any project. Fewer pieces mean faster installation, fewer joints to maintain, and cleaner finished appearance that appeals to modern design preferences.

The efficiency gains compound when you consider specialized installation equipment now available. Suction lifting tools designed specifically for large format pavers eliminate the back strain and safety concerns of manual handling while speeding up the process.

Rooftop spaces represent untapped potential in Long Island’s dense residential and commercial markets. New pedestal systems and lightweight pavers make these installations practical where they were previously cost-prohibitive or structurally impossible.

Modern pedestal systems adjust from half an inch to over 36 inches high, accommodating utilities, drainage, and structural requirements while creating perfectly level finished surfaces. The systems work with various materials—porcelain pavers, wood deck tiles, even artificial turf—giving you flexibility to match client preferences and budget constraints.

Porcelain pavers designed specifically for elevated applications offer unique advantages. They’re fireproof, stain-resistant, and fade-resistant while weighing significantly less than concrete alternatives. For urban Long Island properties where fire codes are strict and maintenance access is limited, these materials solve multiple problems.

The installation process uses adjustable pedestals that eliminate the need for traditional mortar beds or complex drainage systems. Water flows freely underneath the finished surface, preventing the pooling and freeze-thaw damage that plague traditional rooftop installations.

Market demand for rooftop spaces continues growing as property values rise and available land becomes scarcer. Contractors who understand these systems can tap into projects that generate premium pricing while offering clients valuable additional living or commercial space.

Innovation often comes from combining existing technologies in new ways. GeoCeramica represents this approach, bonding porcelain tile to concrete paver bases using proprietary binding agents. The result combines porcelain’s low maintenance and modern aesthetics with concrete’s familiar installation methods and structural properties.

These hybrid systems install like traditional pavers over standard base preparation, eliminating the complexity and cost of tile installation while providing the performance benefits clients associate with high-end materials. For contractors, this means you can offer premium aesthetics without learning entirely new installation techniques.

The practical advantages extend beyond installation. Porcelain surfaces resist staining, scratching, and fading better than concrete alternatives while maintaining slip resistance for safety. The concrete base provides the structural integrity and familiar handling characteristics your crew already understands.

Pricing falls between traditional concrete pavers and full porcelain systems, creating opportunities to upsell clients who want enhanced performance without premium material costs. The combination often proves more cost-effective than achieving similar aesthetics through other methods.

Color and texture options continue expanding as manufacturers recognize market demand. Current selections include wood-look planks, natural stone textures, and contemporary solid colors that complement modern architectural trends popular in Long Island’s evolving residential market.

Understanding these innovations matters, but successful implementation requires choosing the right applications and preparing your team properly. Start with projects where the benefits clearly justify any learning curve—high-visibility installations where performance advantages become selling points for future work.

Consider your client base when selecting which innovations to adopt first. Homeowners focused on long-term value appreciate self-healing mortars and permeable systems that reduce maintenance. Commercial clients often prioritize installation efficiency and performance monitoring capabilities that smart materials provide.

Training investment pays dividends when your crew can confidently discuss and install advanced systems. Clients notice the difference between contractors who understand these technologies and those still relying on traditional approaches. For your next masonry supply needs and expert guidance on implementing these innovations, we at Powerhouse Mason Supply offer the knowledge and inventory to keep your Long Island projects at the forefront of industry advancement.

Article details:

Share: